Chemicals

Filter Fabrics For Chemicals

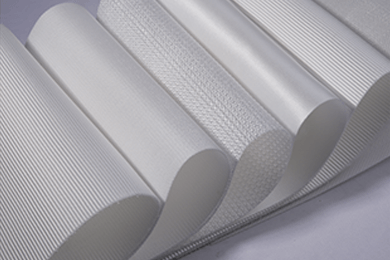

Solid-liquid mixtures are commonly encountered in chemical production. Our company specializes in supplying filter fabrics for two crucial processes: solid recovery to achieve a clarified solution and the purification of waste liquid.

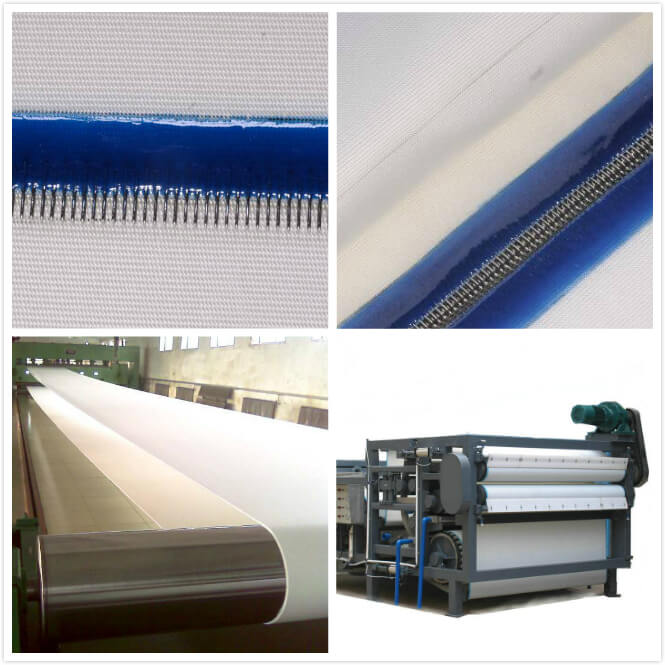

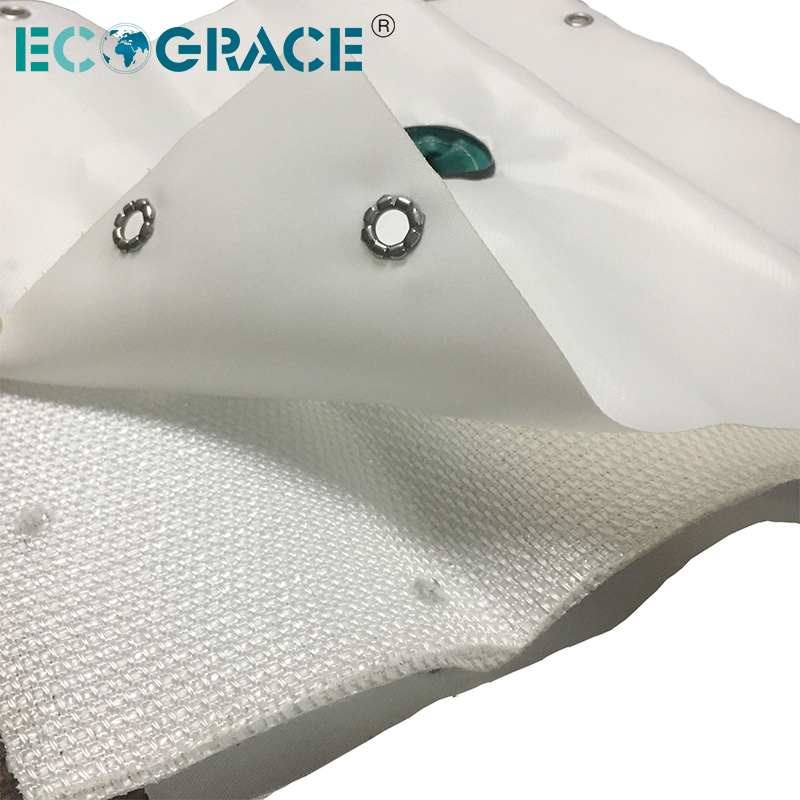

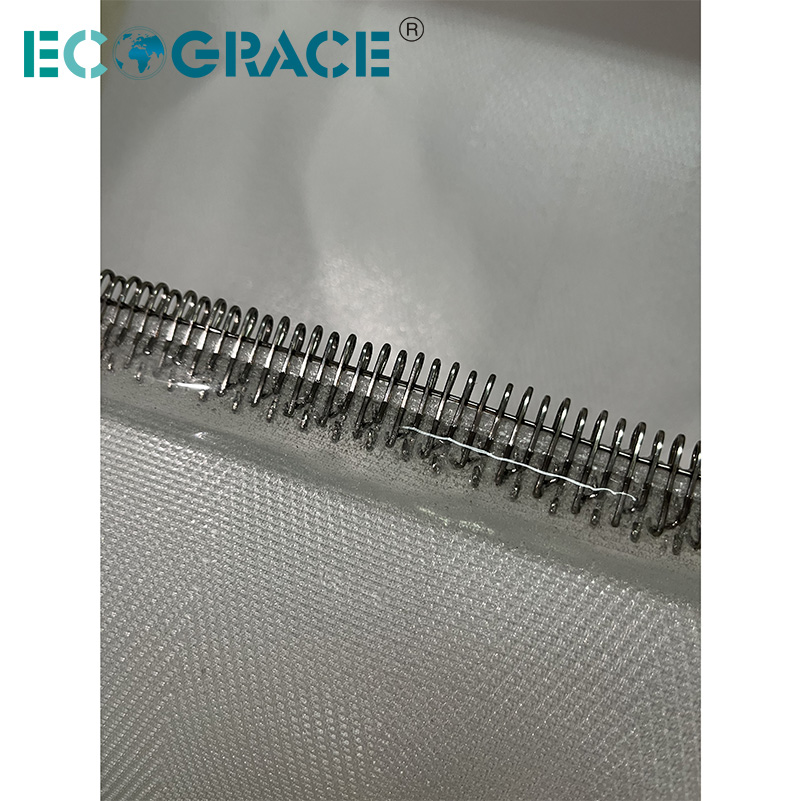

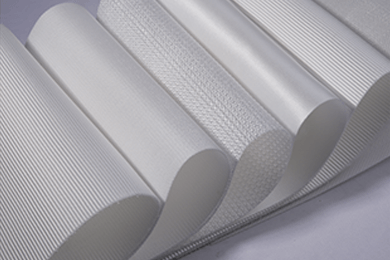

We have complete control over the production and manufacturing of filter fabric belts, filter conveyor belts, non woven filter fabrics, and filter cloth that are compatible with various filtration equipment including tower press filters, horizontal vacuum belt filters, filter presses, and plate press filters.

Our expertise extends to a wide range of applications of filter fabrics, such as Phosphoric acid, pigments, dyes, chemical fillers, Zinc oxide, Activated carbon, Iron oxide, Titanium Oxide, White Carbon Black, Calcium Carbonate,, and more.

What is a filter fabric? What is filter fabric usually made of?

Let’s Start a Conversation

Putting our Expertise on Filter Fabrics to Work for You

Filter Fabrics for Phosphoric Acid

- Factors affecting P2O5 process conditions in phosphate rock include origin, blend, and quality

- Proper selection of filter media is crucial for achieving optimal filtration with high flow rates

- Monofilament fabrics, specifically Polypropylene or Polyester grades, are commonly chosen for this purpose

- The selection depends on the process and equipment type used, such as Horizontal Vacuum Belt Filters and Table Tilting or Non-Tilting Filters

- We offer assistance in finding the ideal balance between acid quality, yield, cost, service life of filter media, and filtration performance.

Filter Fabrics Chemical Fillers

We work for filtration for the pigment and filler industry for many years. The main material are as following:

- Precipitated Calcium Carbonate

- Precipitated Silica

- Kaolin

Fillers and precipitated silica for the tire industry are the fastest growing segments in the industry. We offers a wide range of filter media options to meet the customer needs for high quality, high throughput and high efficiency.

Filter Fabrics for Pigments

- Filtration process in pigment industry requires fine particles and fast throughput

- Developed unique solutions for this industry

- EP6048 performs well in pressure and vacuum applications for colored pigment production

- Improves efficiency of pigment slurry de-watering and maximizes factory’s potential

- EP6048 and EP 6088 are ideal for chamber filter presses, ensuring long service life, high productivity, and easy installation.

Filter Fabrics for Titanium Dioxide

- Provider of titanium dioxide production technology for sulfate or chloride process

- Well-regarded for expertise and advanced technology

- Scientifically chosen fabric selection based on thermal, chemical, and mechanical conditions

- Vertically integrated manufacturing for superior quality control

- Sulfate process involves various filtration stages, each with different conditions and equipment types

- Manufacturing process divided into black section (from ilmenite ore) and white section

| P0802Y | Coal Washing |

| T0803t | Waste Water treatment |

| P050D, P030MD, P020MD | Mud / Slurry Dewatering |

| N9029 | Alumina / Aluminum Oxide |

| N199 | Iron ore concentrate |

| P1010 | Aggregate / Mining |

| P020MD | Leads ore concentrate |

| 9501-35 | Cement Plant |

| 9501-34 | Zinc oxide |

| PT9502b-41DY | Municiple Water / Waste water treatment |

| PT9502b-31 | Gold |

| P750AB | Copper |

| 9502-402DY | Slurry Dewatering |

| P190 | Beer filtration |

| P199s/P11636: | Sugar Plant filtration |

| N120B | Palm oil filtration, |

| 3233SY | White carbon black |

| 3233SY/108C/P801IIy | Kaolin Clay |

| T3112BY/3233SYY | Pigment, dyestuff |

Explore our news, case studies and other information for filter fabrics.

Industrial Filter Fabrics Factory For Mining and Mineral

Our filter fabric for mining and mineral filtration are designed to optimize efficiency and enhance production in the mining industry….

Best Belt Filter Manufacturer For Slurry Drying

Efficient Sludge Dewatering: The Belt Filter Belt – A High-Performance Solution. The sludge dewatering press filter belt is a highly…

Filter Belt For Sludge Dewatering Press

Filter Press Belt: A High-Performance Solution for Efficient Sludge Dewatering The filter belt for sludge dewatering press is a versatile…

Sludge Dewatering Belt For Various Industries

Sludge Dewatering Belt | Efficient Filtering for Various Industries Application of Sludge Dewatering Belt The sludge dewatering belt, also known…

Mining and Mineral Press Filter Cloth

Our Mining and Mineral Filter Press Cloth, the perfect solution to enhance mining efficiency and improve production in the mining…

Just as important as the right filter press system filter press cloth for your application is keeping it up and running. Discover our full range of aftermarket parts and products.

Our Filter Fabrics Customized to YOUR Operation.

We provide solutions operate effectively in a variety of processes such as dewatering, pressing, forming, drying, filtering, separating, screening, and conveying