Filter Press Cloth

Filter Press Cloth

ECOGRACE has decades of experience in the manufacturing of industry-leading filter cloth for filter presses, belt filter press, including chamber filter press, membrane filter press and belt filter press. We are the best manufacturer of filter cloth in Asia, continuing to evolve and expand to meet the increasing high-performance requirements. Our focus is in environmental considerations such as dewatering of Mine Tailings, including MINING & MINERALS, CHEMICALS, FOOD & BEVERAGE, WATER TREATMENT and BUILDING PRODUCTS. ECOGRACE is continuing to innovate with heavy weight, mechanically resistant fabrics with improved dimensional stability, high flow rates and longer service life.

We offer cloth filter press that can be tailored to each process. Over 6 months working life. Additionally, we offer innovative solutions for use across many sectors, and our ECI 600 series which are tailored to specific markets such as Dyes & Pigments and Kaolin. Filter cloth

Description

What is filter press cloth?

Advanced Fabrication Techniques:

We are confident on quality and performance with the filter media that are attached to the press cloth of the plate.

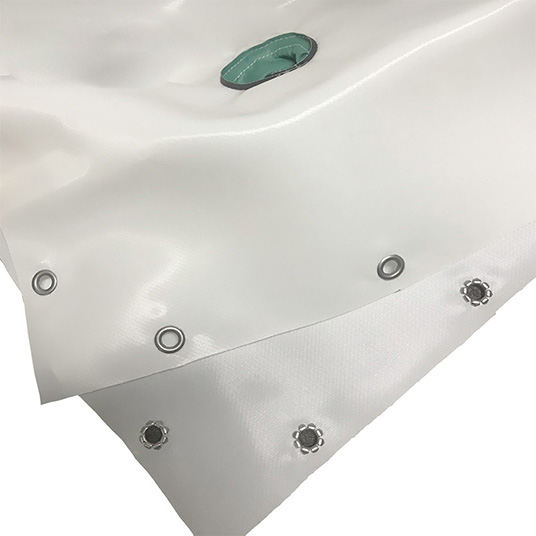

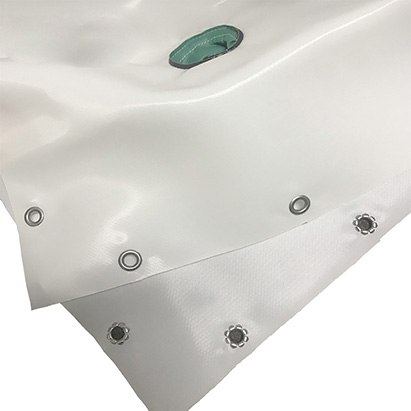

Mine Tailing Sewage Filter Press Fabric

Leading Land Filter Cloth Liquid Solid Separation Filter Cloth is mainly applied for Mining industry , Chemical Industry, Food industry. Mineral tailing concentration, Wastewater treatment , sludge sewage dewatering, kaolin clay , quarry , granite production process,etc.

Mining Industry Filter Cloth Dry Cake Clear Filtration 1500x1500mm, 2100mm x 2100mm , 1100 x 1100 mm

Filter Cloth Application :

Mining Industry :Coal Washing , Tailing of Gold / Zinc / Nickle , Tailing of coal, Kaolin clay, Cement , Aggregate , Asphalt , filter press cloth replacement , etc. polypropylene filter cloth

Environmental protection: Sewage treatment, Sludge dewatering , flue gas desulphurization, Salt mud , fly ash, etc.

Chemical Industry : Pigment , Zinc oxide, Activated carbon, Iron oxide , Nickle, Titanium Oxide, White Carbon Black , Calcium Carbonate , etc.

Steel & Iron ,Metallurgical Industry :Alumina / Aluminum oxide , Iron Ore , Gold, Leads , Vanadium , Nickel , Zinc , Copper, Titanium, etc.

Food processing :Fruit juice, Sugar, Syrup,Beer Eatable Oil , etc.

What material is filter press filter? Which cloth is best for filtering?

Parameters

| Fiber-yarn type | Ecograce code | Weight g/m² | Air permeability @200 Pa l/dm².min | Efficiency | |

|---|---|---|---|---|---|

| Woven fabrics | Polyamide-M | 6028 | 296 | 350 | 2 |

| Polyamide-M | 6026 | 355 | 300 | 2 | |

| Polyamide-M/F | DF 6330 | 270 | 220 | 3 | |

| Polyamide/Polypropylene-M | N5038 | 305 | 500 | 2 | |

| Polypropylene-F | NF4508 | 500 | 20 | 3 | |

| Polypropylene-F | NF4510 | 500 | 5 | 4 | |

| Polyester-F | 2830 | 580 | 30 | 4 | |

| Polyester-F | 4066 | 960 | 5 | 4 | |

| 4068 | 450 | 5 | 3 | ||

| Polyester-F/M | 6910 | 1050 | 50 | 3 | |

| Belts | Polypropylene , Polyester | 3963 | 660 | 50 | 4 |

| 2046 | 550 | 120 | 3 | ||

| 3980 | 720 | 20 | 2 | ||

| 3960 | 750 | 7.5 | 2 |

S=staple | F=multifilament | M=monofilament | 1=poor | 2=medium | 3=good | 4=very good

Photos

Inquiry

Just as important as the right filter press system filter press cloth for your application is keeping it up and running. Discover our full range of aftermarket parts and products.

Press Filtration Customized to YOUR Operation.

With a singular focus on pressing filtration technologies for heavy industry, we design and engineer high-performing systems that are built to handle large volumes of abrasive materials in harsh, highly regulated environments.