Power Generation

FGD Belts Filter Cloth and Dust Filter Bags For Power Generation

Filtration Fabrics For Power Plant

With decades of experience in the Flue Gas Desulfurization FGD filtration stage for regulating the sulfur dioxide (SO2), our expertise lies in designing filter fabrics specifically tailored for FGD applications. We proudly deliver top-performing products for every filtration stage, including Dust Collection, Gypsum slurry Filtration, and Wastewater Filtration. Our filter bags and press filter belts , FGD Belts for FGD systems have gained immense popularity in power generation sites.

FGD Filter Press Belts

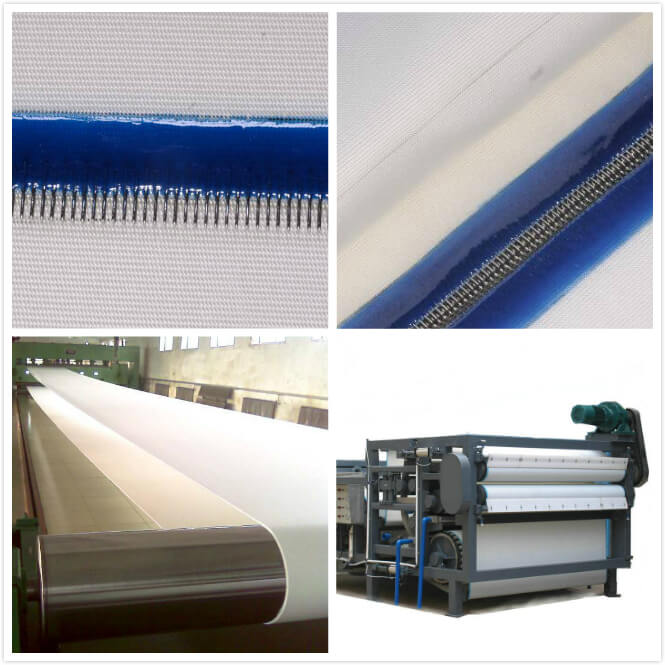

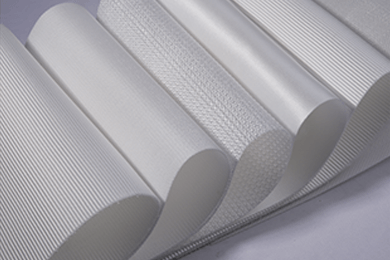

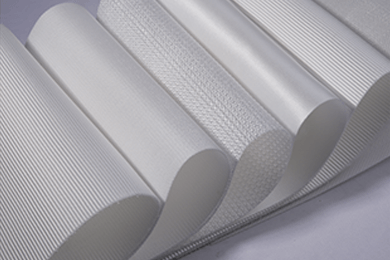

FGD-Tex (10-30 CFM) is a type of fabrics for flue gas desulfurization specifically designed for use in FGD systems, particularly in horizontal vacuum filters and Belt Filter Presses for Gypsum Slurry Dewatering. FGD Belts primary purpose is to effectively filter fine gypsum slurry particles.

FGD horizontal vacuum belt filter fabrics FGD Belts finds extensive application in various scenarios, such as filtering gypsum slurry in FGD plants and filtering coal slurry during coal washing in coal-fired power stations.

In these applications, FGD-Tex serves as a reliable and efficient solution, ensuring optimal filtration performance. For engineers and professionals involved in FGD systems, filter bags, filter belts, and FGD filter belts are crucial components that contribute to the successful operation of the filtration process.

Keyword: belt filter cloth horizontal vacuum, filter cloth, filter press belt, FGD filter belt

Let’s Start a Conversation

Putting our Expertise to Work for You

The initial phase of FGD filtration involves the utilization of dust collector bags commonly employed at different particle transfer stages. With decades of experience in dust collection and air pollution solutions, our expertise lies in pollution control, supplying top-quality fabric filter bags that undergo special treatments to meet operational conditions.

Renowned for their superior quality, our FGD Belt Press Filter Belts are manufactured using heavy-duty polyester filaments to ensure exceptional stability during the filtration and washing processes of Gypsum Slurry, which typically involves handling high volumes.

In the realm of wastewater processing, Filter Presses serve a critical role in purifying water. We collaborate with customers to design filter fabrics that comply with local regulations. This filtration stage typically involves the usage of filter presses and horizontal vacuum belt filters.

Our comprehensive range of filtration products for FGD systems encompasses the following:

- HORIZONTAL VACUUM BELT FILTERS

- FILTER PRESS CLOTHS

- CANDLE SLEEVE FILTER

- DUST COLLECTORS

| P0802Y | Coal Washing |

| T0803t | Waste Water treatment |

| P050D, P030MD, P020MD | Mud / Slurry Dewatering |

| N9029 | Alumina / Aluminum Oxide |

| N199 | Iron ore concentrate |

| P1010 | Aggregate / Mining |

| P020MD | Leads ore concentrate |

| 9501-35 | Cement Plant |

| 9501-34 | Zinc oxide |

| PT9502b-41DY | Municiple Water / Waste water treatment |

| PT9502b-31 | Gold |

| P750AB | Copper |

| 9502-402DY | Slurry Dewatering |

| P190 | Beer filtration |

| P199s/P11636: | Sugar Plant filtration |

| N120B | Palm oil filtration, |

| 3233SY | White carbon black |

| 3233SY/108C/P801IIy | Kaolin Clay |

| T3112BY/3233SYY | Pigment, dyestuff |

Explore our news, case studies and other information for filter cloth horizontal vacuum belt.

Industrial Filter Fabrics Factory For Mining and Mineral

Our filter fabric for mining and mineral filtration are designed to optimize efficiency and enhance production in the mining industry. […]

Best Belt Filter Manufacturer For Slurry Drying

Efficient Sludge Dewatering: The Belt Filter Belt – A High-Performance Solution. The sludge dewatering press filter belt is a highly […]

Filter Belt For Sludge Dewatering Press

Filter Press Belt: A High-Performance Solution for Efficient Sludge Dewatering The filter belt for sludge dewatering press is a versatile […]

Sludge Dewatering Belt For Various Industries

Sludge Dewatering Belt | Efficient Filtering for Various Industries Application of Sludge Dewatering Belt The sludge dewatering belt, also known […]

Mining and Mineral Press Filter Cloth

Our Mining and Mineral Filter Press Cloth, the perfect solution to enhance mining efficiency and improve production in the mining […]

Just as important as the right press filter system for your application is keeping it up and running. Discover our full range of aftermarket parts and products.

Our Filter Press Cloth Customized to YOUR Operation.

With a singular focus on filtration technologies for heavy industry, we design and engineer high-performing systems that are built to handle large volumes of abrasive materials in harsh, highly regulated environments.