Press Filter Belt

Vertical Tower Press Filter Belt

Tower Press Belts are for belt filter press dewatering, for the ultimate filtration solution for a wide range of industries. Whether you’re in the Pigment, Dye, Chemical, Mineral, Pharmaceutical, or Food industry, our filter press belts deliver reliable and efficient filtration.

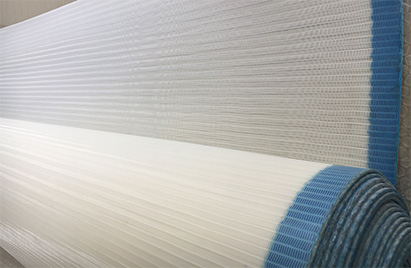

Crafted using high-quality Polypropylene / Polyester materials, these press filter belts are designed with different weave patterns and yarn types to ensure optimal filtration efficiency, cake moisture, and filtrate clarity. They are engineered to provide exceptional performance and produce remarkably dry solids, regardless of whether you’re dealing with coarse or fine grades.

.

Description

Our Tower Press Filter Belt offer a number of benefits :

- Increased productivity of plant

- Save maintenance costs

- Optimized throughput and clarity

- Easy cake release and resistance to blinding

- Lower percentage of solids in filtrate

- Stretch-, shrink- and abrasion-resistant

Advantages of the Vertical Tower Press :

- Compared to a conventional filter press, tower presses have a smaller footprint

- Tower presses automatically discharge sticky filter cakes cleanly meaning lower machine maintenance

- Effective cake washing with minimum use of wash liquor and the ability to wash both sides of the fabric

- shorter cycle time

What does a belt filter press do?

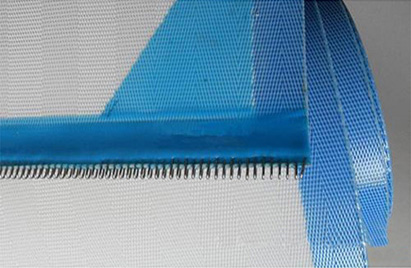

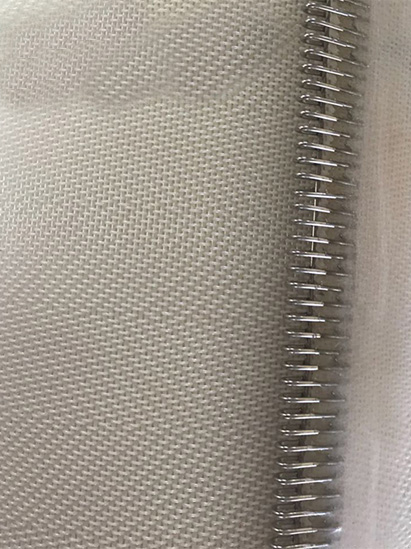

With sealed and reinforced edges, as well as clipper seams, our filter press belts guarantee long-lasting durability and stability. They are specifically designed to meet the demands of rigorous filtration processes, making them a dependable choice for your filtration needs.

Invest in our Tower Press Belts today and experience the outstanding performance and efficiency they bring to your filtration processes

Key words : belt filter presses, phoenix belt filter press, enviroquip belt press filter

For details on how we can tailor Vertical Tower Press Belts to your application, contact the team.

Parameters

| Fiber-yarn type | Ecograce code | Weight g/m² | Air permeability @200 Pa l/dm².min | Efficiency | |

|---|---|---|---|---|---|

| Woven fabrics | Polyamide-M | 6028 | 296 | 350 | 2 |

| Polyamide-M | 6026 | 355 | 300 | 2 | |

| Polyamide-M/F | DF 6330 | 270 | 220 | 3 | |

| Polyamide/Polypropylene-M | N5038 | 305 | 500 | 2 | |

| Polypropylene-F | NF4508 | 500 | 20 | 3 | |

| Polypropylene-F | NF4510 | 500 | 5 | 4 | |

| Polyester-F | 2830 | 580 | 30 | 4 | |

| Polyester-F | 4066 | 960 | 5 | 4 | |

| 4068 | 450 | 5 | 3 | ||

| Polyester-F/M | 6910 | 1050 | 50 | 3 | |

| Belts | Polypropylene , Polyester | 3963 | 660 | 50 | 4 |

| 2046 | 550 | 120 | 3 | ||

| 3980 | 720 | 20 | 2 | ||

| 3960 | 750 | 7.5 | 2 |

S=staple | F=multifilament | M=monofilament | 1=poor | 2=medium | 3=good | 4=very good

Inquiry

Just as important as the right dust collection system for your application is keeping it up and running. Discover our full range of aftermarket parts and products.

Dewatering Filter Press Fabrics Customized to YOUR Operation.

With a singular focus on pressing filtration technologies for heavy industry, we design and engineer high-performing systems that are built to handle large volumes of abrasive materials in harsh, highly regulated environments.