Wastewater Treatment

Wastewater Treatment

Wastewater treatment filtration is demanded in many market sectors including mining and mineral, chemical industry, power generation, building material (sand, gravel ,cement, quarry, granite, aggregate,etc.) and pulp and paper industry.

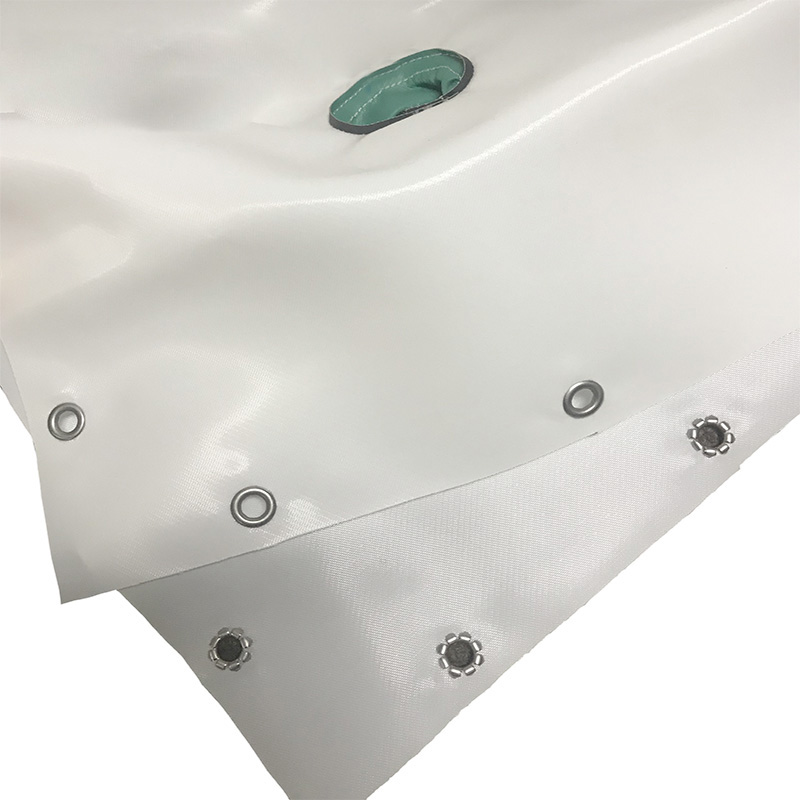

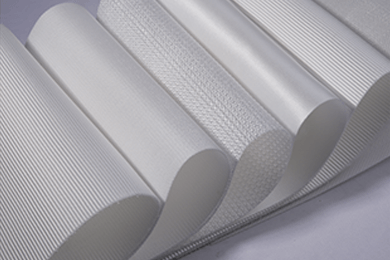

Our press filter conveyor belts are for dewatering and formiing“cake.” Dewatering wastewater solids reduces the volume of residuals, improves operation, and reduces costs for subsequent storage, processing, transfer, end use, or disposal among other benefits.

Let’s Start a Conversation

Putting our Expertise to Work for You

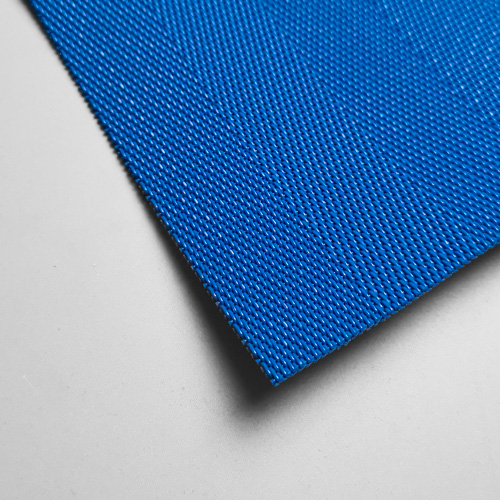

We have an extensive range of filter fabrics developed for industrial waste water including:

- Plate Filter Press

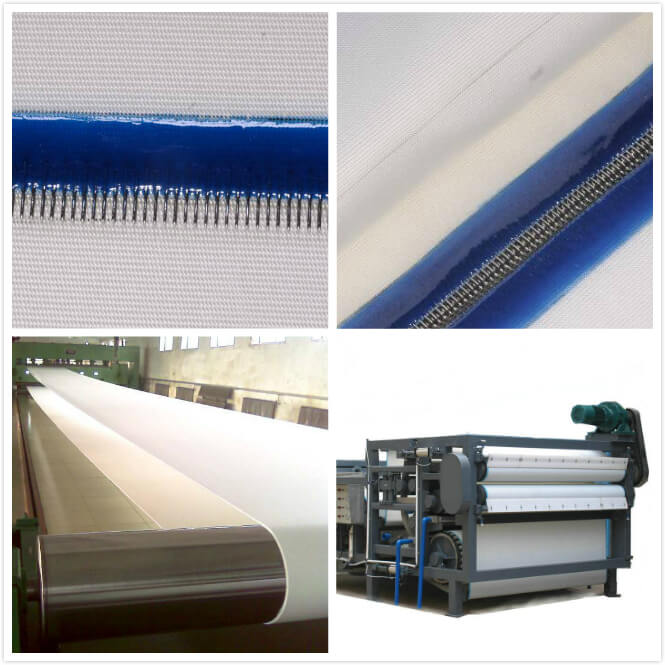

- Belt Filter Press

- Gravity Belt Filter

- Multi Roll Belt Press Filter

- Rotary Vacuum Drum Filters

Aggregates wastewater treatment Filter Conveyor Belts

ECOGRACE specializes in filtration solutions for the aggregates industry, quarry, marble and granite, specifically tailored for the preparation of clean aggregates necessary in various construction applications.

Our expertise lies in the utilization of our filter press cloth and belt press filter technologies for efficient dewatering of wastewater and aggregate washing processes.

Our solutions ensure optimal dewatering, aided by the implementation of our filter cloth, filter press, and belt filter technologies.

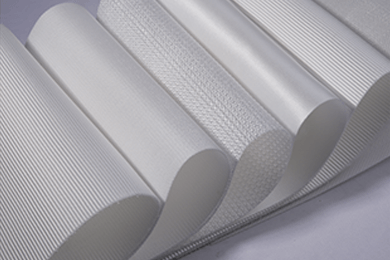

monofilament spiral fabric with improved, fabric with improved hydrolysis resistance, spiral fabric with improved hydrolysis

Clean aggregates are essential to the building industry for the preparation of concrete for many additional uses. ECOGRACE specified in filtration fabrics for the aggregates industry.

| P0802Y | Coal Washing |

| T0803t | Waste Water treatment |

| P050D, P030MD, P020MD | Mud / Slurry Dewatering |

| N9029 | Alumina / Aluminum Oxide |

| N199 | Iron ore concentrate |

| P1010 | Aggregate / Mining |

| P020MD | Leads ore concentrate |

| 9501-35 | Cement Plant |

| 9501-34 | Zinc oxide |

| PT9502b-41DY | Municiple Water / Waste water treatment |

| PT9502b-31 | Gold |

| P750AB | Copper |

| 9502-402DY | Slurry Dewatering |

| P190 | Beer filtration |

| P199s/P11636: | Sugar Plant filtration |

| N120B | Palm oil filtration, |

| 3233SY | White carbon black |

| 3233SY/108C/P801IIy | Kaolin Clay |

| T3112BY/3233SYY | Pigment, dyestuff |

Explore our news, case studies and other information.

Industrial Filter Fabrics Factory For Mining and Mineral

Our filter fabric for mining and mineral filtration are designed to optimize efficiency and enhance production in the mining industry. […]

Best Belt Filter Manufacturer For Slurry Drying

Efficient Sludge Dewatering: The Belt Filter Belt – A High-Performance Solution. The sludge dewatering press filter belt is a highly […]

Filter Belt For Sludge Dewatering Press

Filter Press Belt: A High-Performance Solution for Efficient Sludge Dewatering The filter belt for sludge dewatering press is a versatile […]

Sludge Dewatering Belt For Various Industries

Sludge Dewatering Belt | Efficient Filtering for Various Industries Application of Sludge Dewatering Belt The sludge dewatering belt, also known […]

Mining and Mineral Press Filter Cloth

Our Mining and Mineral Filter Press Cloth, the perfect solution to enhance mining efficiency and improve production in the mining […]

Just as important as the right pressing filter system for your application is keeping it up and running. Discover our full range press filter belts.

How does a belt filter press work?How efficient is a horizontal belt filter?

Our filter press cloth and belt press filters are for de-watering wastewater and aggregate washing processes. Materials washing and scrubbing processes is for removing clay or other materials, separating and graveling the materials, de-watering are the key process. dimensional stability and strength retains, resistance smooth surface and high.

Keywords: filter cloth, filter belt, filter conveyor belt, filter press cloth, vacuum filter belts

Our Filter Conveyor Belts Customized to YOUR Operation.

With a singular focus on pressing filtration technologies for heavy industry, we design and engineer high-performing systems that are built to handle large volumes of abrasive materials in harsh, highly regulated environments.