Pulp and Paper

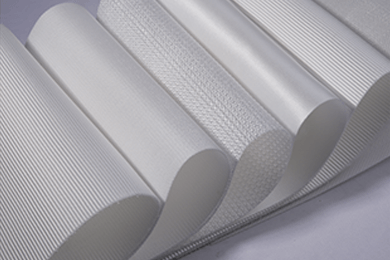

Filter Press Belts for Pulp and Paper

Our expertise lies in the filtration stages of pulp and paper processes, including brown stock washing, bleach pulp washing,for solidliquid separation, dewatering, and sludge dewatering. The pulp and paper processing industry requires filtration systems and the selection of the appropriate filter belts, filter fabrics, and filter cloth is crucial for for product wastewater treatment solutions.

Process Description:

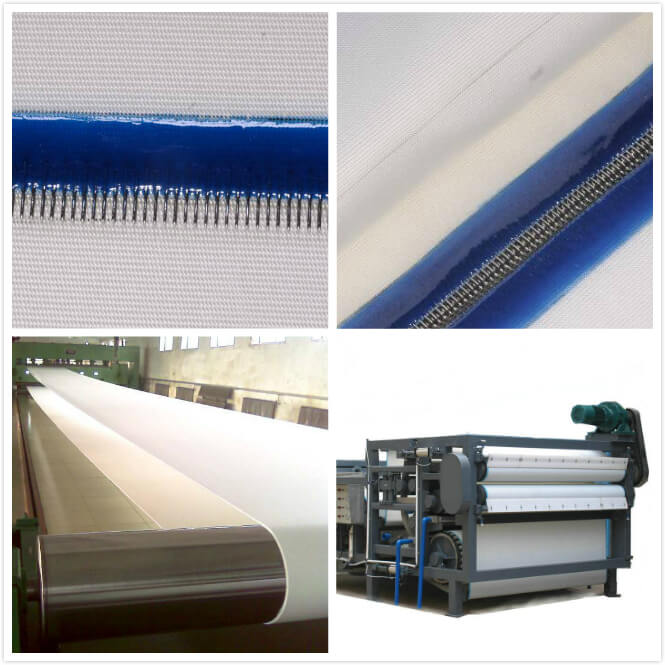

What does a belt filter press do? Belt filter presses utilize one or more endless or seamed belts to dewater wet sludge, facilitating a progressive dewatering process. This involves gravity drainage, low-pressure-assisted drainage, and high-pressure-induced drainage. Various machine configurations are employed to achieve these functions and create effective belt filter presses.

Our filtration solutions including everything from understanding production costs to achieving the desired level of separation or efficiency. We offer a wide range of filter press belts, filter fabrics, and filter cloth to meet your specific needs in the pulp and paper industry.

Let’s Start a Conversation

Putting our Expertise to Work for You

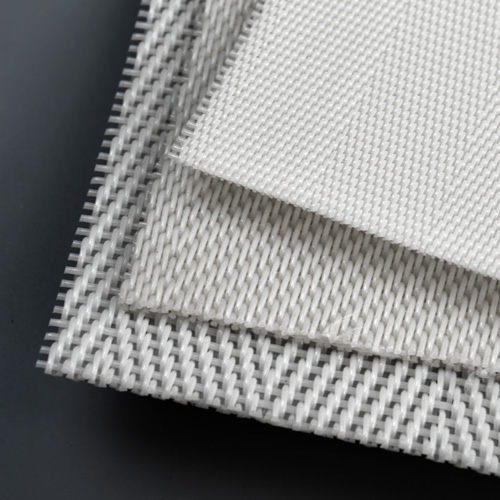

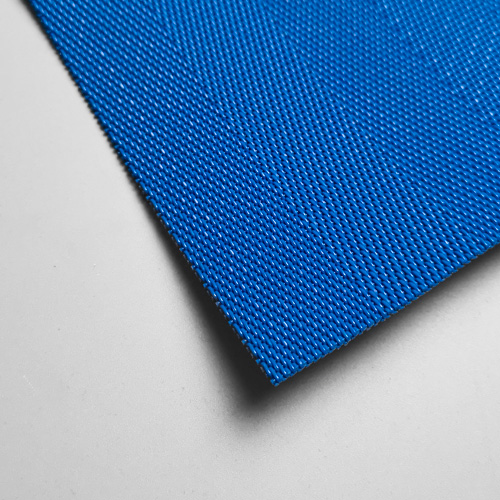

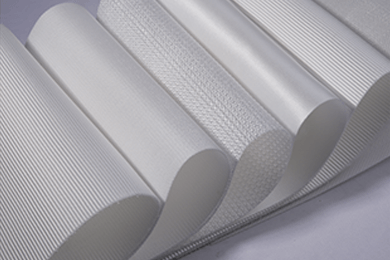

ECOGRACE offers a full range of filter belts, filter fabrics, and filter cloth tailored to the specific requirements of pulp extraction processes. Our filtration fabrics are designed to ensure effective solid and liquid separation throughout the washing, thickening, and dewatering stages. Specifically, we have developed filter media optimized for each step, including filter press belts for brown stock and bleach pulp washing stages, as well as multi-roll belt filters for efficient dewatering and sludge dewatering.

Our exclusive range of filter media for pulp processes include:

- FILTER PRESS CLOTHS

- GRAVITY THICKENER BELT

- HORIZONTAL VACUUM BELT FILTER

- MULTI-ROLL BELT FILTER

- ROTARY VACUUM DISC FILTER

- ROTARY VACUUM DRUM FILTER

- TOWER FILTER PRESS

Keywords: belt filter press manufacturer, filter cloth, filter belt, press filter belt, filter press manufacturer belt

| P0802Y | Coal Washing |

| T0803t | Waste Water treatment |

| P050D, P030MD, P020MD | Mud / Slurry Dewatering |

| N9029 | Alumina / Aluminum Oxide |

| N199 | Iron ore concentrate |

| P1010 | Aggregate / Mining |

| P020MD | Leads ore concentrate |

| 9501-35 | Cement Plant |

| 9501-34 | Zinc oxide |

| PT9502b-41DY | Municiple Water / Waste water treatment |

| PT9502b-31 | Gold |

| P750AB | Copper |

| 9502-402DY | Slurry Dewatering |

| P190 | Beer filtration |

| P199s/P11636: | Sugar Plant filtration |

| N120B | Palm oil filtration, |

| 3233SY | White carbon black |

| 3233SY/108C/P801IIy | Kaolin Clay |

| T3112BY/3233SYY | Pigment, dyestuff |

Explore our news, case studies and other information.

Industrial Filter Fabrics Factory For Mining and Mineral

Our filter fabric for mining and mineral filtration are designed to optimize efficiency and enhance production in the mining industry. […]

Best Belt Filter Manufacturer For Slurry Drying

Efficient Sludge Dewatering: The Belt Filter Belt – A High-Performance Solution. The sludge dewatering press filter belt is a highly […]

Filter Belt For Sludge Dewatering Press

Filter Press Belt: A High-Performance Solution for Efficient Sludge Dewatering The filter belt for sludge dewatering press is a versatile […]

Sludge Dewatering Belt For Various Industries

Sludge Dewatering Belt | Efficient Filtering for Various Industries Application of Sludge Dewatering Belt The sludge dewatering belt, also known […]

Mining and Mineral Press Filter Cloth

Our Mining and Mineral Filter Press Cloth, the perfect solution to enhance mining efficiency and improve production in the mining […]

Just as important as the right belt pressing system for your application is keeping it up and running. Discover our full range of filter products.

Our Filtration Fabrics Customized to YOUR Operation.

With a singular focus on filter press fabrics technologies for heavy industry, we design and engineer high-performing systems that are built to handle large volumes of abrasive materials in harsh, highly regulated environments.